Natural gas is a naturally occurring mixture of hydrocarbons (HCs) and non-hydrocarbon gases such as N2, H2S, and CO2.

Hydrocarbons provide the energy content we seek in natural gas. This resource plays a vital role in energy production and industrial development, offering a cleaner alternative to coal and oil.

However, this has been made to ease with the use of specific gravity (SG), where any gas with an SG in the range of 0.55 to 0.65 is lean, meaning it has high HC content.

Since the natural gas is so ‘natural’ as it’s generated from organic matter deposited in the subsurface, the only means to tap into it is through a gas well.

We won’t go any further into exploration, even though, before drilling, several activities are done to determine the well location.

Now you have the resource (let’s call this supply, as in economics), getting the supply to where it’s demanded sets forth a whole new complex challenge of its own.

This is where transportation comes, predominantly, the industry was occupied by pipeline as the major means of transportation.

But as the energy deficit grew (still growing as a matter of fact), more far-far demands grew as well. Now we had to think innovatively about taking the supply to demand, just as in economics 101.

Pipelines are still in play, but they have a threshold of ~ 2000 km; a length beyond that is considered uneconomical, although it can be justified by the demand size (RoI).

Then, the non-pipeline technologies were introduced with LNG as the mother of all transporting vast volumes of natural gas (1 unit of LNG ≡ 600 units of natural gas), taking the supply to where it’s demanded the most without consideration of the where or how distance the demand is.

Other non-pipeline technologies include CNG, GTL, NGH, and GTP in some circumstances.

We shall dwell more on LNG from here.

Liquefied Natural Gas (LNG)

Recalling the states of matter, we understand that anything can exist either as a solid, liquid, or gas.

Natural gas at ambient temperature exists as a gas, dropping the temperatures to cryogen levels (extremely low temperatures, below -150°C), the gas now becomes a liquid.

LNG in specific is attained at -162°C (-260°F). A room of 3x3x3m filled with gas can be occupied in a cube of 0.3m length in its liquid form; typically, 1/600th of the gas is what it is in liquid form, and this is the case for LNG.

The cooling process has a specific name, Liquefaction, giving meaning to the “L” in LNG. Natural gas, from the definition, we now know it contains HC and non-HC gases; LNG’s prerequisite is C1 (most of you know it as methane).

Removing the non-HC and heavier HCs is done in a process known as gas processing.

Gas Conditioning/Pretreatment

Gas processing involves a number of steps/procedures, all dependent on the gas content. It can run from dehydration, Hg (mercury) removal, heavy hydrocarbon removal, to deamination (removing amines), or more steps. In general, this is what we call Conditioning or Pretreatment.

Liquefaction

The conditioned gas is now suitable for liquefaction. Since the 1970s, when LNG was introduced, the liquefaction technologies have changed depending on the scale of application, where for small-scale applications, we have modular solutions that require less time in setup/construction as well as manufacturing.

Thermodynamically speaking, LNG is an expansion cycle at its core:

“When a gas expands (i.e., its pressure drops), its temperature decreases.”

The latest inventions have been built on top of the same foundation with refrigerant cycles, mixed refrigerant cycles, nitrogen cycles, etc.

Storage & Transportation

Once the gas is cooled, it’s then stored or shipped. Since it is attained at very low temperatures, the tanks used to store LNG must be cryogenic tanks.

The tankers have membranes inside, which set the primary barrier. These membranes are made of a special steel, like Invar, which has negligible thermal contraction, ensuring the liquid remains liquid.

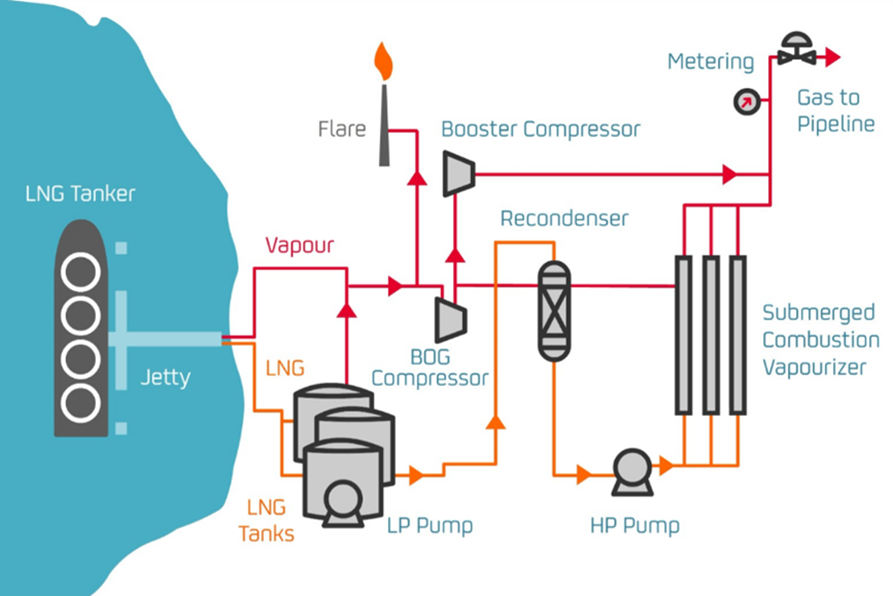

Shipped as a liquid, upon arrival at the demand, the supply is then converted back to gas, and this is known as regassification, as you can see below.

Regassification is done since we can’t utilize the gas in its liquid form, although there are some engineered applications in transportation where vehicles use LNG directly as the fuel.

But these specific conversions require sturdy engineered works plus a bit more investment in the beginning to enable conversion or duality (mostly Diesel & LNG). If it’s something you are interested in, we would be happy to assist with this. Check our contact page for more.

Gas usage all remains the same worldwide energy generation: electricity and heating at industrial levels, cooking and warmth at residential levels.

In summary, LNG is a 3-step procedure with liquefaction as the main theme, setting the tone and changing the name from natural gas to LNG.

Energy Outlook

I’ll take you back to that economics part now that we know how the supply (LNG) is made. Japan started importing fuel, mostly LNG, in the 1960s. It has funded and supported various LNG project initiatives in the world, and to a greater extent in the US.

By then US dominated the market but was overtaken by Asian producers when projects started across the Middle East and Australia.

Apart from Japan, Europe is seemingly the next demand point with ~ 12% of its energy coming from imported LNG (2022 -2023). With the ongoing campaigns on clean and secure energy, most initiatives will turn to LNG; thus, the recent burst in SS-LNG plants (mini-LNG projects).