In industrial maintenance and repair, the ability to perform repairs, modifications, improvements, and reinforcements without the need to interrupt production operation is an integral part of the process itself. The major attributes of such repairs include cost savings and minimized downtime.

A few engineering procedures that can attain this at one go are hot tapping & In service welding. Hot tapping is an industrial term that originates from two distinct aspects of the maintenance procedure: hot work (welding) and precise drilling (tapping).

The Hot Tapping process allows a connection into a pressurized in-service (operating) system by drilling or cutting.

The hot tap procedure involves attaching a branch connection and valve on the outside of an operating pipeline, cutting out the pipeline wall within the branch, and removing the wall section through the valve.

In general, hot taps are done in a piping system. But it can also be done on pressure vessels and storage tanks to add nozzles and outlets that were not there to begin with.

Hot tapping is a highly dangerous operation. Therefore, hot tapping is a last resort when it is impractical to shut down the system/plant for maintenance.

What is Hot Tapping?

Hot tapping is a pressure installation technique that allows new connections to be made on an existing live (operating) line or equipment without shutdown or interruption to critical plant operation.

“Hot tapping is the technique of attaching connections to equipment in service by welding and drilling.” (API Publication 2201)

This operation is carried out on a live (hot) system or line without decommissioning. The ability to perform modification and remedial work without interrupting operations makes hot tapping an indispensable skill in hundreds of industries. In the welding context, it is commonly used for any welding onto in-service equipment.

Hot tapping can be applied to a wide range of piping or equipment materials, from carbon steel, cement, and PVC, regardless of the location, whether on land (onshore) or underwater (offshore).

Problems can occur when welding onto a pressurized pipe if the unmelted area beneath the weld pool is not strong enough to contain the internal pressure of the pipe. The rule of thumb is that the greater the wall thickness, the less risk of burn-through.

Common terminologies in context are

| Term | Definition |

| Run Pipe | The pipe into which a hot tap is to be made. |

| Branch Pipe | The pipe is to be connected to the run pipe by means of the hot tap. |

| Coupon | Section of pipe cut out during the hot-tap cutting operation. |

| Lock Plug | A plug that can be set into position inside a hot-tap connection flange to retain internal pressure. |

| In-service Welding | Welding on a piping system that is flowing or under pressure |

Justification of Hot Tapping

Shutdown interconnect (Historical cold tees) methods for creating pipeline connections or remedial work are still used, although often at the cost of disruption of operations for days, increased emissions (O&G industry), and more risk.

Hot tapping involves safety hazards and is undertaken when the required modification can’t be delayed until the next available shutdown. The decision to choose between a hot tap and a shutdown interconnect lingers upon a comparative analysis between the two.

Hot tap configuration

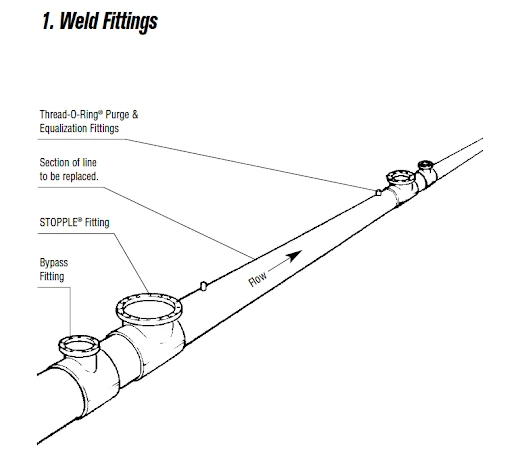

A successful hot tap deploys the use of valves, fittings, and the hot tapping machine to achieve completion. Fittings are one of the primary components of any hot tapping procedure and are designed with a variety of options to make the branch/new connections an exact fit.

Dimensions such as the size and pressure of a vessel, as well as the bore size of the tap itself, are fundamental to determining the type of fitting. Along with the general fittings, there are also High and low-pressure fittings which specialize in pressure variant or control.

All of the fittings are welded into place in preparation for the hot tapping procedure. The welds are usually inspected on site, i.e., X-ray radiography, or some use specific software such as PRCi to check for weld strength.

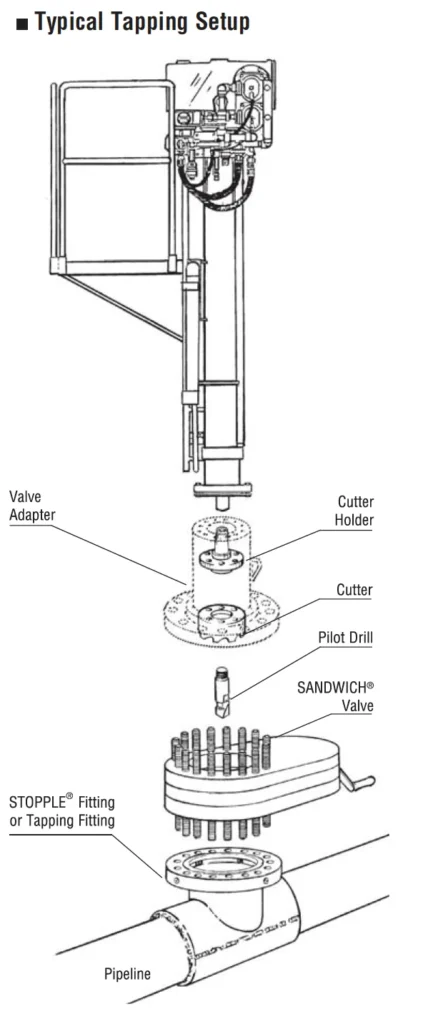

Once the fittings are welded in place set of sandwich valves is placed on top and ready to receive the hot tapping machine to begin the procedure. The general setup or configuration for this is as seen below,

Steps in hot tapping

Despite the “hot” nature of hot tapping and risks inherent in pressurized operational tanks, piping, and pipelines, it remains a thoroughly planned, calculated, and controlled procedure.

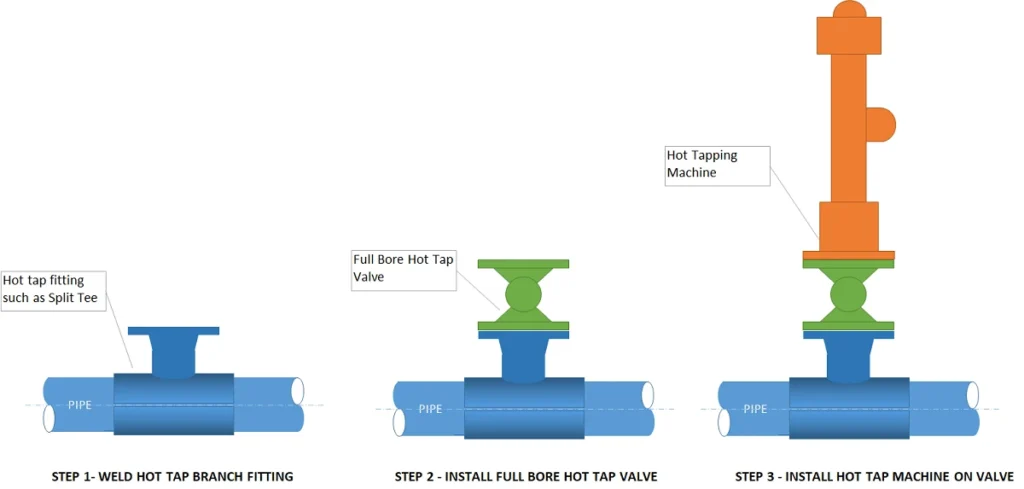

Hot-tap operation involves the following basic steps

- Welding a suitable tapping fitting, such as a split tee or reinforced flanged fitting.

- Installing a hot-tapping valve.

- Installing the hot-tapping machine on the valve to execute the pressure cut, which involves the removal of a section of run pipe.

Standards and regulations

Due to its criticality, the process is regulated in adherence to various standards from ASME on fitting fabrication to API on performing the hot tap. Some of the applicable standards are

- ASME PCC-2 – Article 216 Welded Hot Taps in Pressure Equipment or Pipelines.

- API RP 2201 – Procedure for Welding or Hot Tapping on Equipment in Service.

- API STD 1104 – Welding of Pipelines and Related Facilities.

- API RP 2200 – Repairing Hazardous Liquid Pipelines.

Limitations of hot tapping

Safety is a number one priority in many of the maintenance operations or procedures. Most engineering specifications in relation to hot tapping do not permit the execution of the procedure under the following conditions.

- Lines or vessels containing Acids, caustics, Elemental Sulfur, Oxygen, Chlorine, Ammonia, and any other partially toxic material.

- Pipes, tanks, or vessels with wall thickness below 6mm (This increases the risk of burn-through during welding).

- Piping and equipment that has internal coating, cladding, glass, cement, or refractory lining.

- Piping and equipment that are jacketed.

- Piping and equipment that are subject to vacuum.

- Piping where slugging can occur during the hot-tapping operation.

For more, you can further read section 216-2.4 of ASME PCC-2 (2018) for a more detailed and comprehensive list of conditions that pose unacceptable risks for hot tapping.

What does the future hold for hot tapping?

Almost a century old now, hot tapping is more relevant to energy systems in the present day than ever before. With increasing advancement in safety and reliable execution, hot tap became a preferable choice.

The inevitable result has led to the growth of such applications across every sector the procedure applies to.

Apart from saving the cost associated with downtime, hot tapping represents a significant benefit to the environment. Hot tapping reduces emissions associated with the product venting of miles of pipeline/tanks/vessels necessary for cold tee shutdown procedures.